Precision sheet metal parts made with experience

Our sheet metal processing technologies guarantee precision, which is strengthened by our advanced quality management system.

Hans Pausch Hungaria offers innovative solutions combined with traditional experience for all your sheet metal processing requirements.

Well-trained and motivated employees guarantee a first-class product.

Hans Pausch Hungaria can be relied upon as an experienced supplier in the field of sheet metal fabrication.

A company that, as a supplier, offers a wide range of solutions for all the needs of its customers.

Regardless of the industry in which you operate.

On top of laser cutting, punching, bending and spot welding services, we can provide additional blacksmith solutions.

One-stop service from raw material through cutting and forming process to the finished product.

Our fleet is well equipped to meet our customers design needs, regardless of the industry which you operate in.

We are prepared to serve demands from prototyping to series production.

Complex sheet metal processing at Hans Pausch Hungaria

Discover at Hans Pausch Hungaria Kft. the advantages of our advanced sheet metal processing techniques. We pride ourselves on providing solutions that are not only high quality, but also efficient and cost-effective.

Our expertise in sheet metal processing enables us to develop customized solutions, that are precisely tailored to the needs and specifications of our customers.

Sheet metal production for the medical industry: Precision and quality at Hans Pausch Hungaria

Sheet metal based design is an essential part of medical technology. At Hans Pausch Hungaria, we are proud to be a trusted contract manufacturer of the medical sector for more than 25 years. We are only using high quality materials and advanced technologies, to produce precise sheet metal parts for the healthcare industry. This guide is designed to give you an overview of the various processes and materials used in our sheet metal production.

Our sheet metal production

- Laser cutting

High precision production of complex 2D shapes.

Fast and flexible, ability to process diverse raw materials.

Suitable for high and low quantity manufacturing.

Depending on the material selection, we are able to cut up to 15mm thickness.

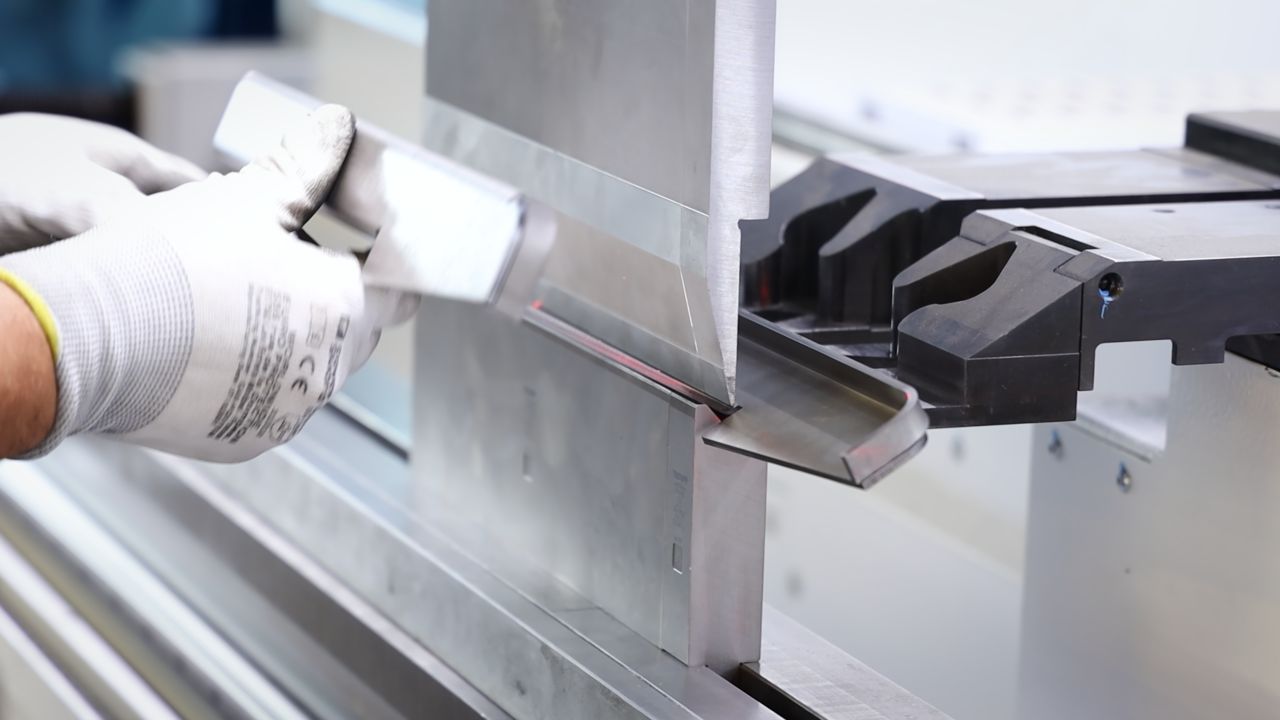

- Bending and folding

CNC controlled press brake systems are offering fast-flowing production combined with precision.

Due to its flexibility, it allows us to produce high complexity 3D parts using wide selection of raw materials.

We can work with up to 3200mm bending length.

- Punching

Fast and cost-efficient process for high volume production, up to 5mm material thickness.

- Others

Our production fleet is prepared for additional custom solutions including design specific tooling.

Material selection

- Carbon Steel

Cost efficient material with high strength.

Generally preferred for structural and complex parts, where durability matters.

- Stainless Steel

Strength, durability, corrosion resistance and low maintenance with the benefit of great appearance.

Stainless steel is one of the most commonly used material when product lifespan matters.

- Aluminium

Lightweight and versatile raw material, commonly preferred to be used for complex designs.

Good corrosion resistance and appearance.

Wide selection sub-variants of the listed are available in our range.

Feel free to send us your enquiry with the specific material of choice.

Quality control

Quality assurance is a crucial aspect of sheet metal processing, especially in medical technology, where requirements are often very high. At Hans Pausch Hungaria, we use state-of-the-art measurement techniques and quality management systems, to ensure all parts meet our high standards.

Why Hans Pausch Hungaria is the ideal partner for sheet metal processing in Hungary?

With a production site in southern Hungary, we can offer easily accessible manufacturing on competitive rates, while maintaining first-class quality. Sheet metal fabrication is a critical process in numerous industries. Hans Pausch Hungaria, with over 25 years of valuable experience in the industry, introduces itself as your ideal partner for sheet metal parts manufacturing.

Technological excellence and expertise

Hans Pausch Hungaria has established itself as a leading company in sheet metal and steel processing. Our modern production facilities are equipped with the latest technologies, which combined with the traditional experience allows us to implement complex projects, with the highest precision and efficiency. Our main activities include laser cutting, punching, bending, welding and assembling solutions.

Competitive prices with high quality

Significant benefit of sheet metal processing in Hungary is the competitive prices. Thanks to lower production costs compared to other European countries, we can offer high-quality services at attractive prices. This is particularly interesting for international customers who are looking for cost-efficient but high-quality solutions.

Strategic location for export

Our production site in southern Hungary offers a geographically advantageous position for export to the European market.

The well-developed logistics infrastructure of the region – including road transport, railways and air freight – allows us to minimize delivery times and reduce transport costs.

Highly qualified professionals

We attach great importance to the training and qualification of our employees. Our team is known for its technical skills, expertise and precision.

We believe these are critical for manufacturing products, that meets the strict requirements of the healthcare industry, just like many others.

Comprehensive service

Our offering has been developed to be able to provide single source solutions, starting with design to the delivery of finished products.

A special focus at Hans Pausch Hungaria is the assembling of complete units. We are offering a comprehensive service package, where products are available to be distributed or used for our customers. This allows our partners to have an optimized supply chain, while maintaning high quality product range thanks to our quality control.