Industrial grade surface treatments at Hans Pausch Hungaria

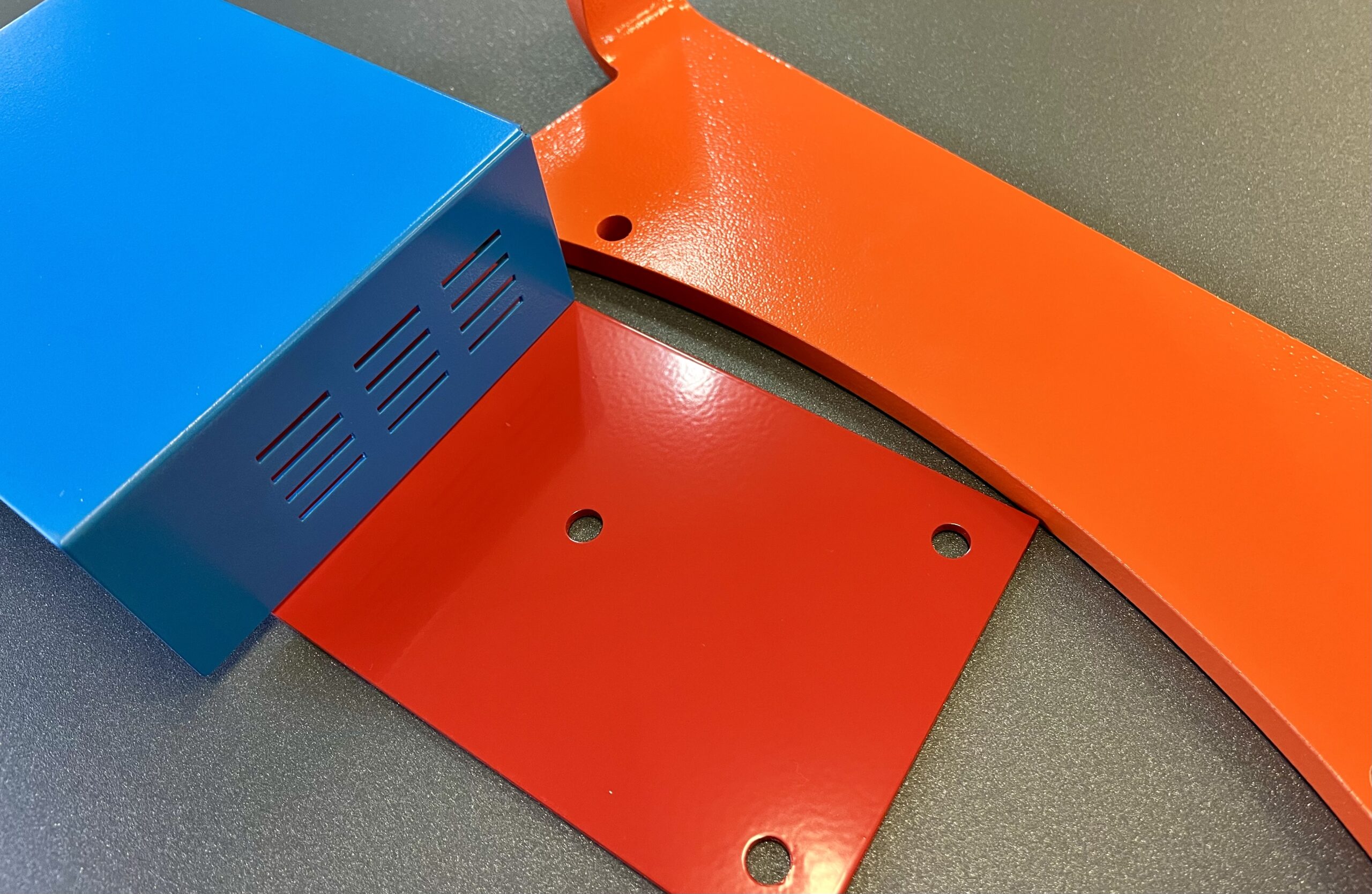

Even when a part has been fabricated with the most precise manufacturing, great appearance is a must for producing high quality parts. Aesthetics is a deciding factor in case of an end product, it needs to look and feel right. It is just not pretty when the paint is peeling off a part. That is why Hans Pausch Hungaria pays special attention to the impeccable appearance of the products during surface treatment processes.

In case of certain parts, protection from the elements and against corrision has significant role, for function and durability. The team of Hans Pausch Hungaria is able to produce flawlessly coated parts, thanks to the decades of experience and extensive know-how in high quality production. Just like in case of all our other production departments, we pay great attention on countinous evolution of our surface treatment department. We are prodly taking the extra step to provide the desired surface finish and we take the effort of appropriately preparing the fabricated parts for the painting process.

Painting process for great appearance

Part of our single source offering is the possibility of in house industrial grade painting service. We have the possibility to use spray paint method or the more productive powder coating solution. Having the painting department on site means faster production and flexibility, also a great addition when combined with our assembling solution. Wide selection of painting material is always available from stock, but our procurement department is able to source more options when needed according to custom specifications.

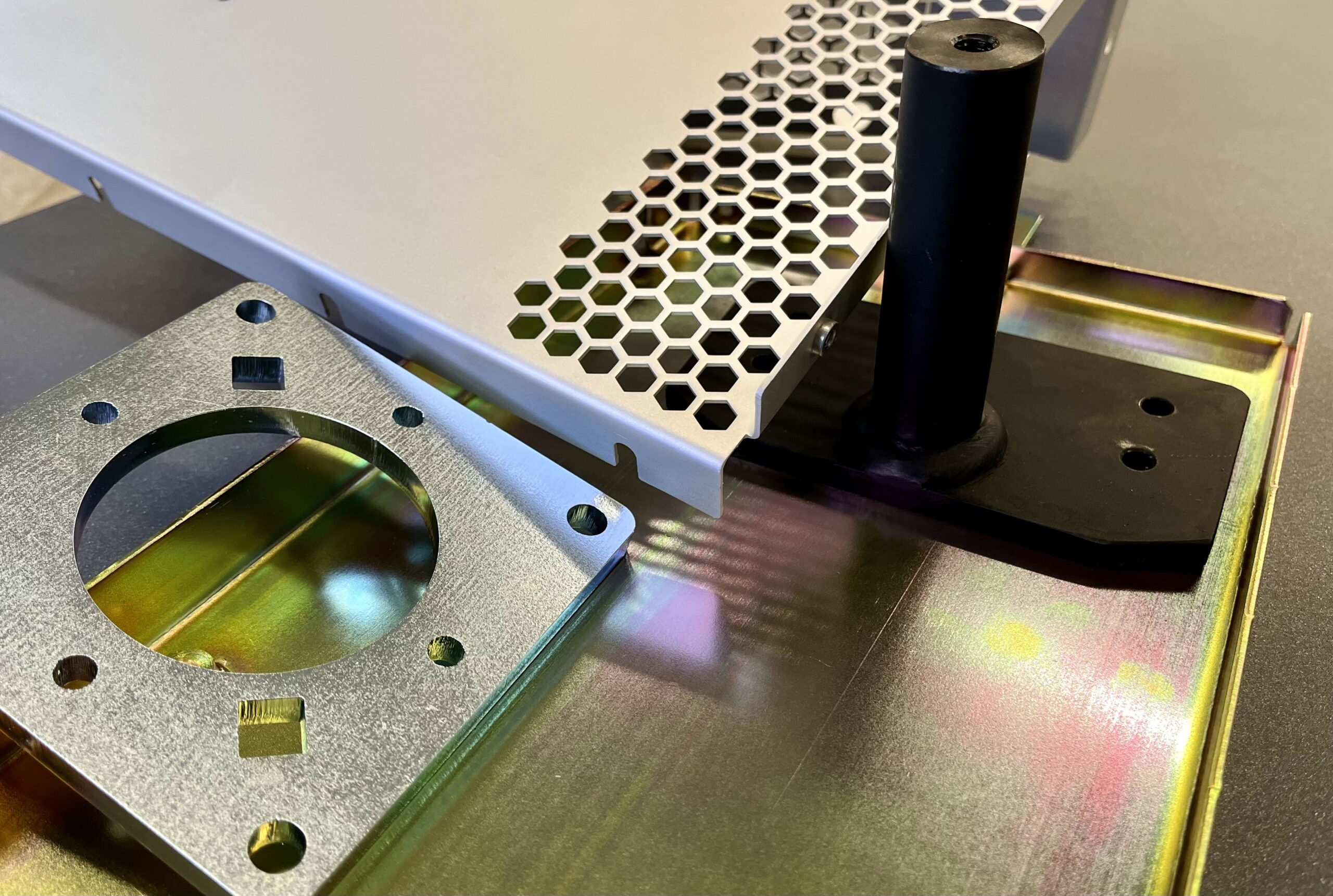

Functional surface treatment solutions

For certain use of parts, paint protection is not a sufficient solution. For that reason you can find further surface tratment solutions in our range of services.

Electroplating

- Galvanizing

- Zinc coating

- Chrome plating

- Nickel plating

- Anodizing

Chemical surface treatments

- Phosphate coating

- Blackening

- Surtec

Feel free to send us your enquiry with the specific surface treatment of choice.

Assembly and industrial painting in contract manufacturing at Hans Pausch Hungaria

At Hans Pausch Hungaria Kft. you receive an industrial coating that meets the highest quality standards. We understand that the appearance of your products is an essential part of your brand image, so we work with the utmost care and precision.

Would you like to find out more about our industrial coatings or would you like individual advice? Contact us – we will be happy to help you find the optimum solution for your requirements.

What makes Hans Pausch Hungaria’s industrial painting special?

Our industrial painting is characterized by the highest quality and precision. We use state-of-the-art technologies and materials to ensure the durability, corrosion protection and aesthetic appearance of your products. Our experienced technicians guarantee consistently high processing quality.

Can you paint different materials?

Yes, we have the capacity and expertise to paint a wide range of materials, including metal, plastic and other specialty materials. Our processes are optimized to match the specific properties of each material in order to achieve the best results.

How do you guarantee the quality of the paintwork?

Quality assurance is a central component of our painting process. We carry out regular checks to ensure that every paint job meets our high standards. This also includes constant monitoring of the painting environment to ensure optimum conditions for each project.

Can you fulfill special painting requirements?

Absolutely. We work closely with our customers to develop customized painting solutions that are specifically tailored to their needs. Whether it’s special color shades, surface qualities or specific technical requirements, our team is ready to take on these challenges.

How do you integrate painting into the overall component assembly process?

Painting is an integral part of our overall process. We ensure that painting is seamlessly integrated into component assembly to guarantee efficiency and consistency. This integrated approach enables us to ensure fast and efficient production without compromising on quality.